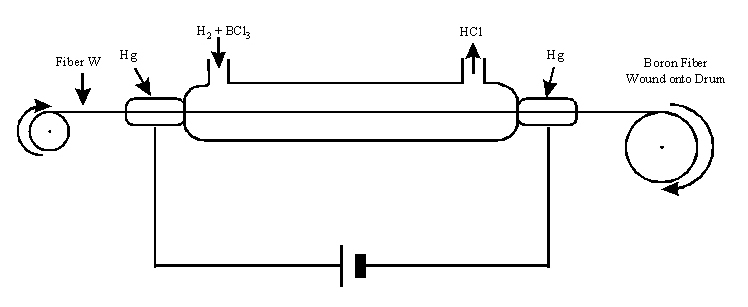

Boron fibers are produced by depositing the boron onto a pre-existing filament such as tungsten or glass. The boron is deposited by chemical vapor deposition of a mixture of boron trichloride (BCl3) and hydrogen (H2) and heated to ca. 1000 oC. The boron is deposited in the form of nodules onto irregularities in the filament. Some of the boron atoms actually penetrate the filament and cause the filament to expand in diameter. A typical diameter for a boron coated tungsten fiber is approximately 140 mm. Boron coated aluminum fibers can be found in the American space shuttle. However, their wide use has been restricted due to their high cost.

Silicon-carbide fibers are also produced by chemical vapor deposition. They are formed by the reaction of silane and hydrogen gases with the carbon filament being the substrate for deposition. They have mechanical and physical properties equal to those of boron and can be used at higher temperatures than boron fibers. Also, they are less expensive and are available in production quantity. Silicon-carbide fibers are generally used in glass, ceramic and glass-ceramic matrices. these fibers retain usable strengths at up to 1000 oC (1832 oF), and have the unique characteristic of retaining basic fiber strength in molten aluminum for up to half an hour.

Ref:

Lee, Stuart M. International Encyclopedia of Composites, Vol. 2, 1990,

VCH Publishers, New York, pp 147.