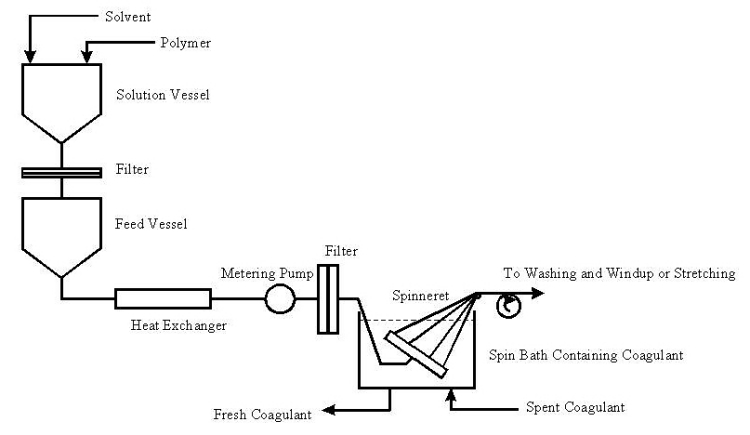

Wet spinning is the most complex of the spinning

techniques. Some wet spinning process require the polymer solution

to be kept above or below ambient temperature and thus a heat exchanger

is used. The spinnerets are immersed in tanks containing the coagulation

into which the filaments are extruded. The extrusion direction is

variable from vertically upwards to horizontal. The spinnerets used

in wet-spinning can have up to 2,000 holes for commercial applications.

However, conventional wet spinning is the slowest of the principal processes

having windup speeds to approximately 150 m/min.

This process is based on precipitation only, without

chemical regeneration. The solvent diffuses out of the extrudate

into the bath, and a non-solvent diffuses from the bath into the extrudate.

The polymer precipitates as a gel initially at the extrudate-coagulant

interface but progressively throughout the extrudate. The coagulation

rate has a large influence on the gel structure and the final fiber properties.

The processing variables are concentration and temperature of the spinning

solution, composition, concentration and temperature of the spin bath;

and the stretch applied during spinning. These conditions lower the

spin-bath temperature, and lower stretch during spinning. These conditions

lead to greater homogeneity and higher orientability in a subsequent stretching

or drawing process and hence to better tensile properties. The spin

bath and spinning solutions may include small amounts of modifying agents

that tend to improve homogeneity of the spun yarn. The coagulated

filaments pass over a guide to driven rollers. The steps succeeding

coagulation vary according to the product but typically include washing,

stretching, finish application, drying, crimping, controlled relaxation

for a tow, plus cutting for a staple fiber product.

A table of typical wet-spinning solvents

and coagulants.

Ref:

Kroschwitz, Jacqueline I. Encyclopedia of Polymer Science and

Engineering. Second Edition, Vol. 6. John Wiley & Sons. New York.

1986 pp. 812-815.