Impact Testing of Selected Coatings

Teacher Notes

Objective:

Impact testing is used to evaluate the the point at which the coating fails to protect the substrate by being degraded. Evidence of the point of failure includes but not limited to the coating cracking , chipping, or completely separating form the substrate. You should lead a class discussion on the usefulness of impact testing and how to go about such testing. Students might come up with some interesting ways to perform the tests. A hammer struck on a surface might suffice. But try to lead the discussion to an organized approach with measurable results. Science works that way! Where would such testing be important and what applications are evident?

Materials:

- Prepared substrates on aluminum foil from the coatings preparation activity and the impact tester which consists of a tube,

- a set of three marbles (use the big marbles in a marble pack available at WalMart),

- and a glass jar (50 mm in diameter by 50 mm high).

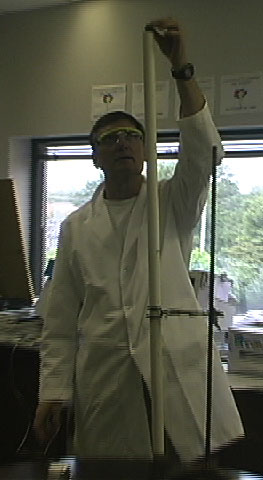

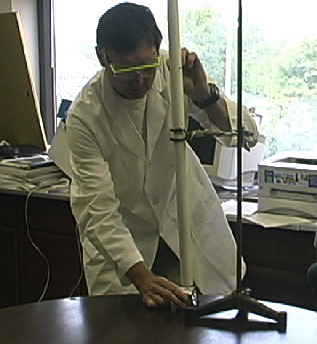

- The impact tester is made from a 4 foot piece of 1 inch PVC pipe available at any local hardware store. Drill a small hole perpendicular to the tube that is centered 15 cm from one end. The hole should be just large enough to loosely accommodate a nail. Continue to drill holes at 15 cm intervals down the tube. You should have approximately 10 cm remaining on one end so that a number of marbles can be held at the 105 cm mark.

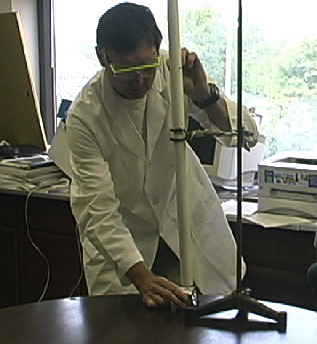

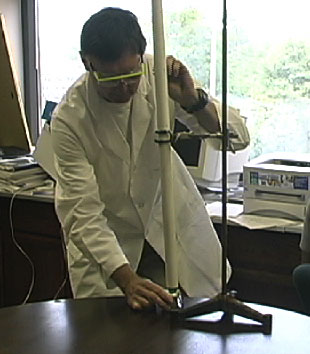

- Use a ring stand and clamp to support the tube over the jar.

- Position the tube so that the first hole is 15cm from the end closest to the jar.

Safety:

Eye protection should be observed throughout this activity.

Procedures:

- Obtain coatings on prepared substrates and impact tester.

- Place the aluminum strip with coating side up over jar opening so that the strip completely covers the jar opening

- Place the nail provided with the tube into the 15 cm hole so that the nail goes through the tube and provides a barrier for the marble.

- Mass the marble you will use in the test and drop it into the tube so that it rests above the nail at the 15 cm mark.

- Center the tube over the jar containing the strip at least 1.0 cm above the jar. Measure the distance from the top of the strip/jar to the bottom of the tube and record that distance.

- While holding the sides of the strip firmly to the sides of the jar, pull the nail out of the tube.

- Carefully removed the marble from the strip and observe the results of the impact of the marble on the coating.

- Repeat steps 2 through 7 using an untested portion of the strip and increasing the distance the marble falls by 15 cm by moving the nail further up the tube.

- Continue to increase the distance the marble moves until the coating deforms to the point determined by your team and teacher. You might set a scale on distance of crack or break in the coating and other deformations. Possibly students could perform one test and then meet as a group to discuss how to interpret the results.

- If after 105 cm the coating shows no sign of deformation, use a second marble and repeat the process starting at the 15 cm mark. If after 105 cm the two marbles show no deformation, use a third marble. Continue the process until the coating deforms.

We approximated the acceleration due to gravity as10m/s2(9.8 m/s2). The force of a 20.0g marble would be :

F = mxa = (.020kg)(10m/s2) = .2N

To find the Nm of energy of the impact of the marble on the coating, multiply the force, in the example .2N by the distance the marble travels in meters. Use the distance at which deformation first takes place. Using the above information the following coatings failed at the specified Nm:

- Armor all car wax .03 Nm

- Krylon fusion 0.09 Nm

- Krylon spray enamel and Kilz spray 0.12 Nm

- 100% acrylic latex and oil based enamel over 0.6 Nm

Analysis:

Develop a suitable means to visually present your findings to include a comparison of impact resistance to type of coating tested. The report also should include the thickness of coating and the thickness of the substrate. The Reynolds heavy duty aluminum used in our tests was 0.07 mm in thickness and coatings were categorized as thin or thick.

Conclusion:

Write a summary of your analysis and include which type of coatings would be suitable for high impact use such as coatings on toys and low impact use such as coatings on furniture.

Polymer Science Learning Center | Department of Polymer Science | University of Southern Mississippi

Copyright ©1995-2003