Adhesives

Up until the early part of the twentieth century adhesives used in plywood

manufacture were available only from natural materials such as hide, bone,

casein, soybean, and other vegetables. These natural adhesives were

not very moisture resistant and while wonderful for indoor uses as one

can imagine that use of these materials outdoors resulted in outright

failure.

In the 1930's the intoduction of synthetic resins such as urea-formaldehyde

(while urea-formaldehydes see primarily indoor use) and phenol-formaldehyde

allowed greater applications in outdoor environments due to their greater

water resistance.

.

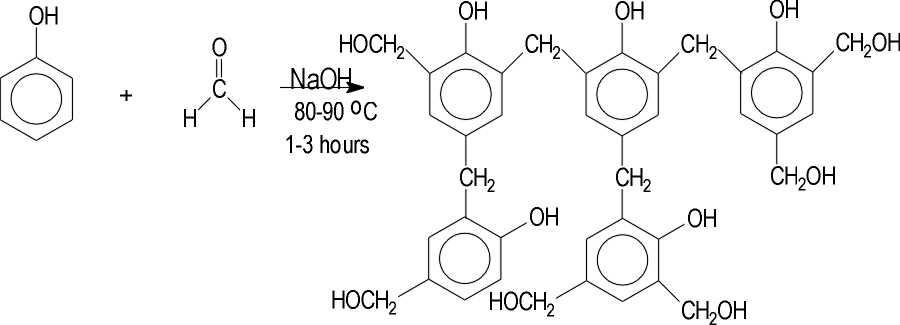

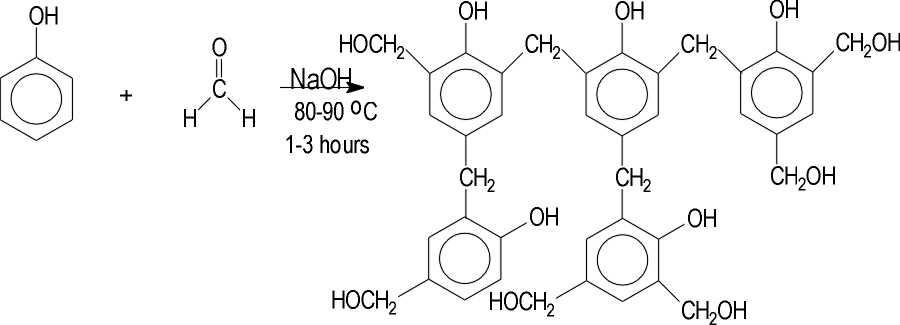

Phenol

and formaldehyde are typically formulated in a ratio of 1:1.2-3 and heated

in the presence of catalyst to form a low molecular weight polymer.

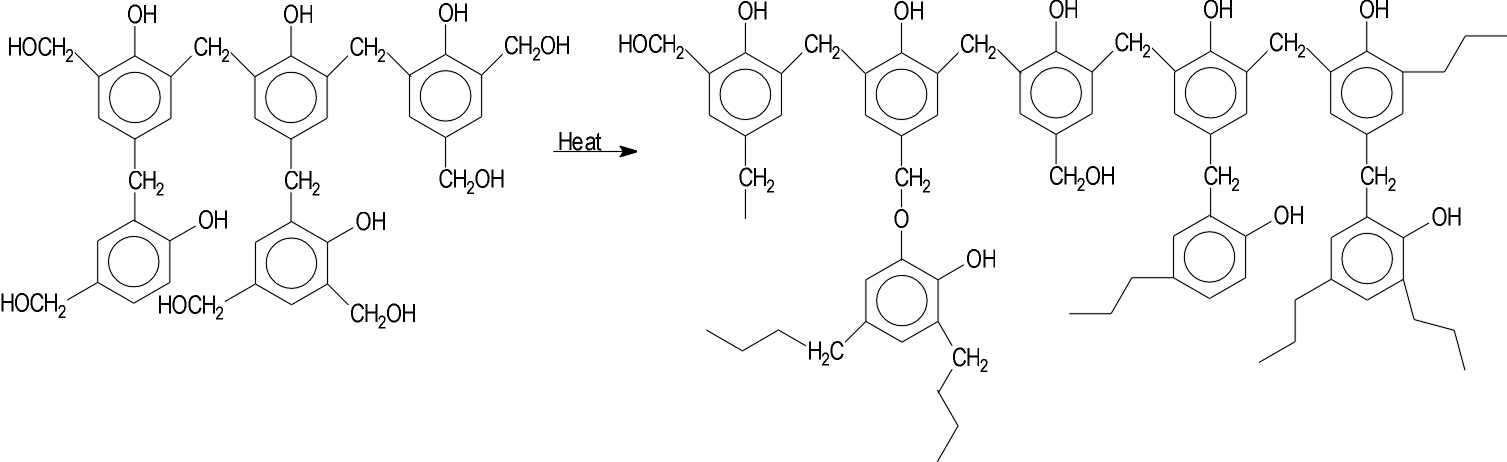

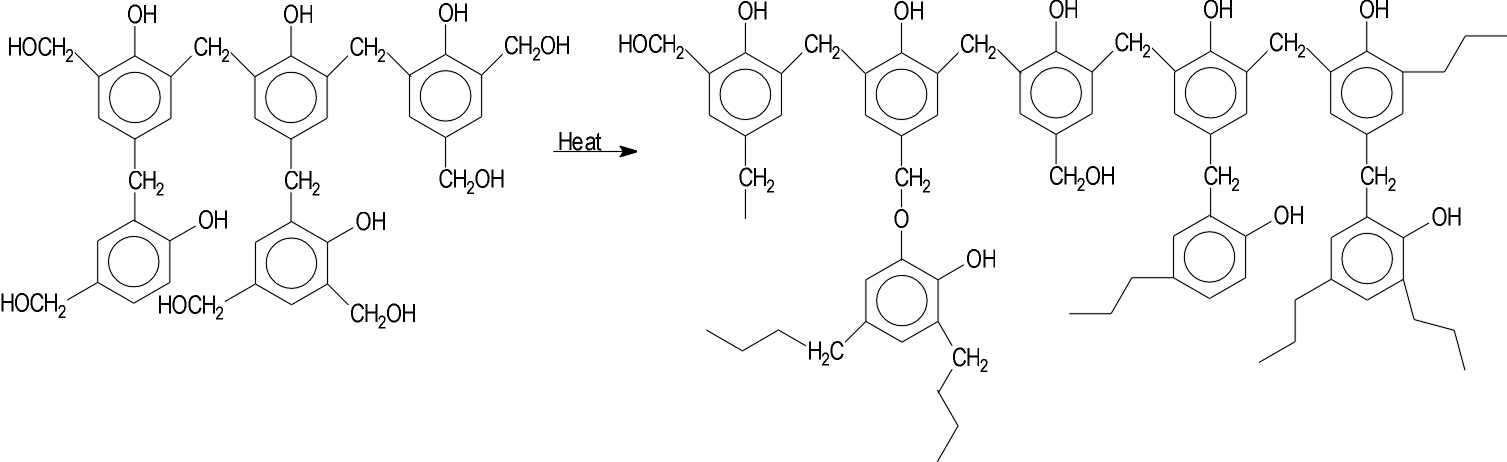

The

polymer precursor is then applied to the substrate and then heated to approximately

180oC and a crosslinked network is formed with methylene and

ether linkages.

Similar chemistries are used with urea, melamine, other phenols, formaldehydes

and other aldehyde derivatives under a variety of conditions.

Return

to plywood.

Return

to particle board.