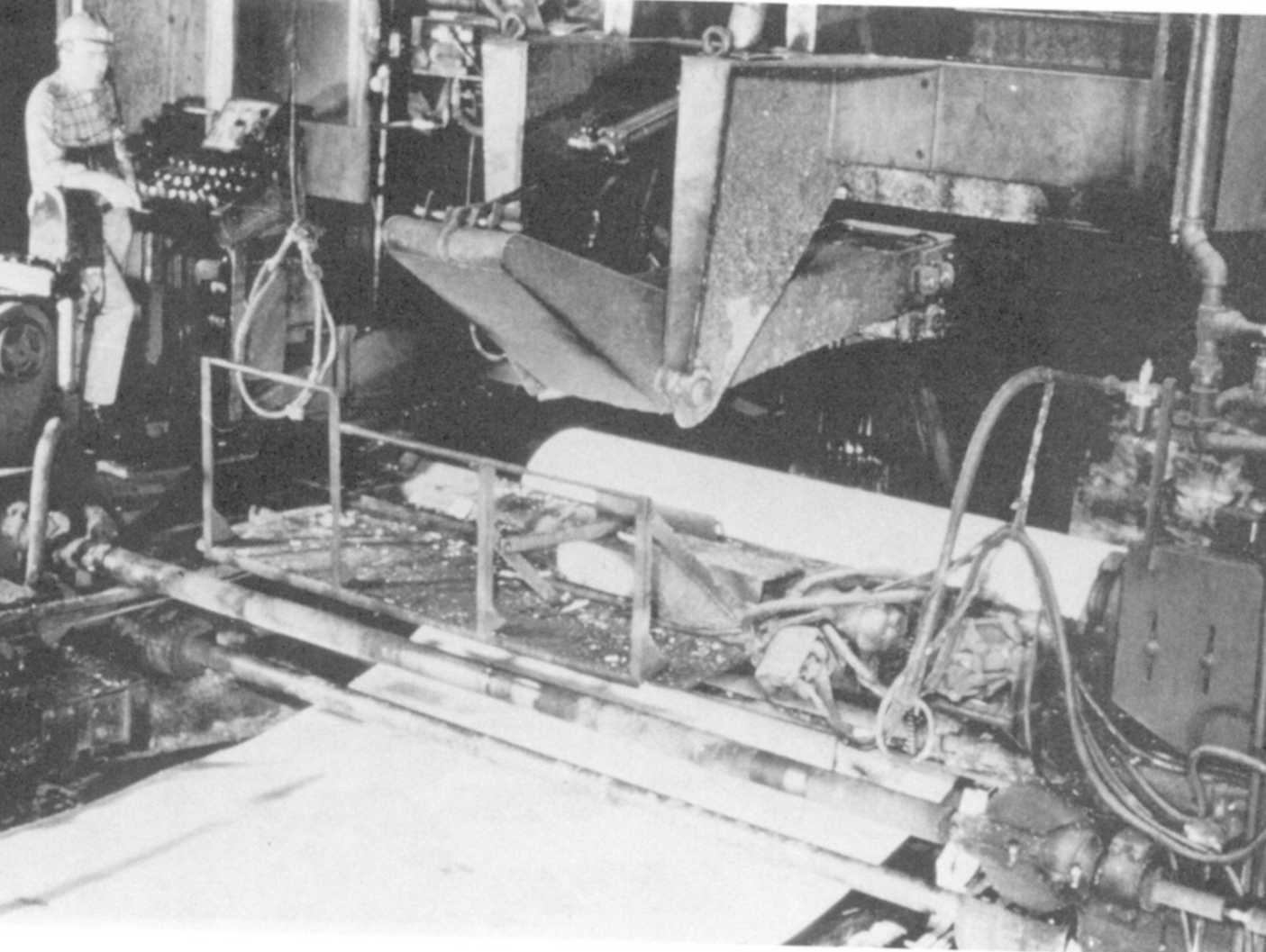

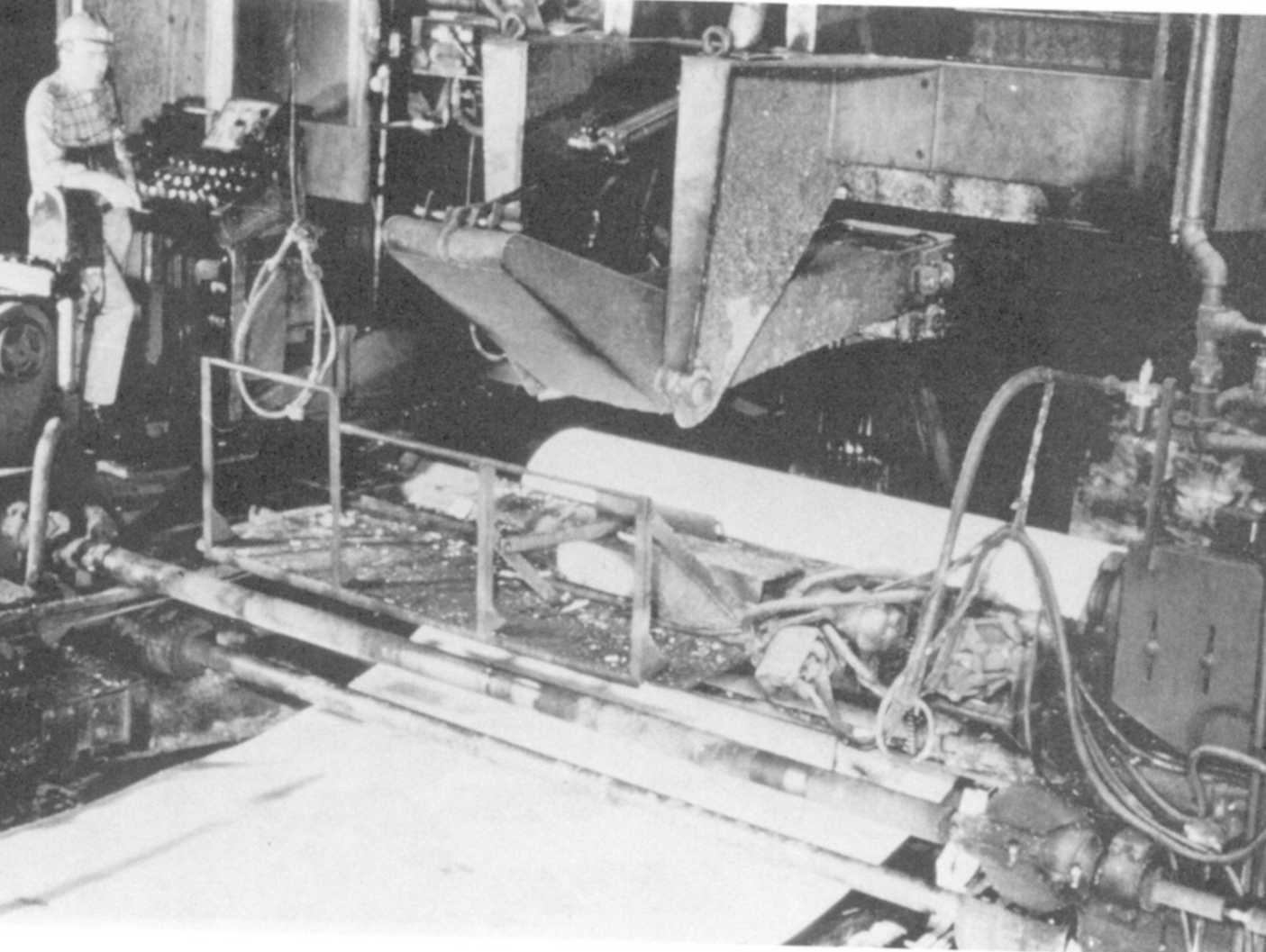

Rotary lathing of a softwood.

Manufacturing of veneers is virtually the same from tree to tree. Logs are debarded and cut into a desire length (either for ease of hanling or a specific application.) The logs are then heated with steam or hot water to soften the materials for cutting.

There

are three basic ways to make veneer:

Rotary lathing of a softwood.

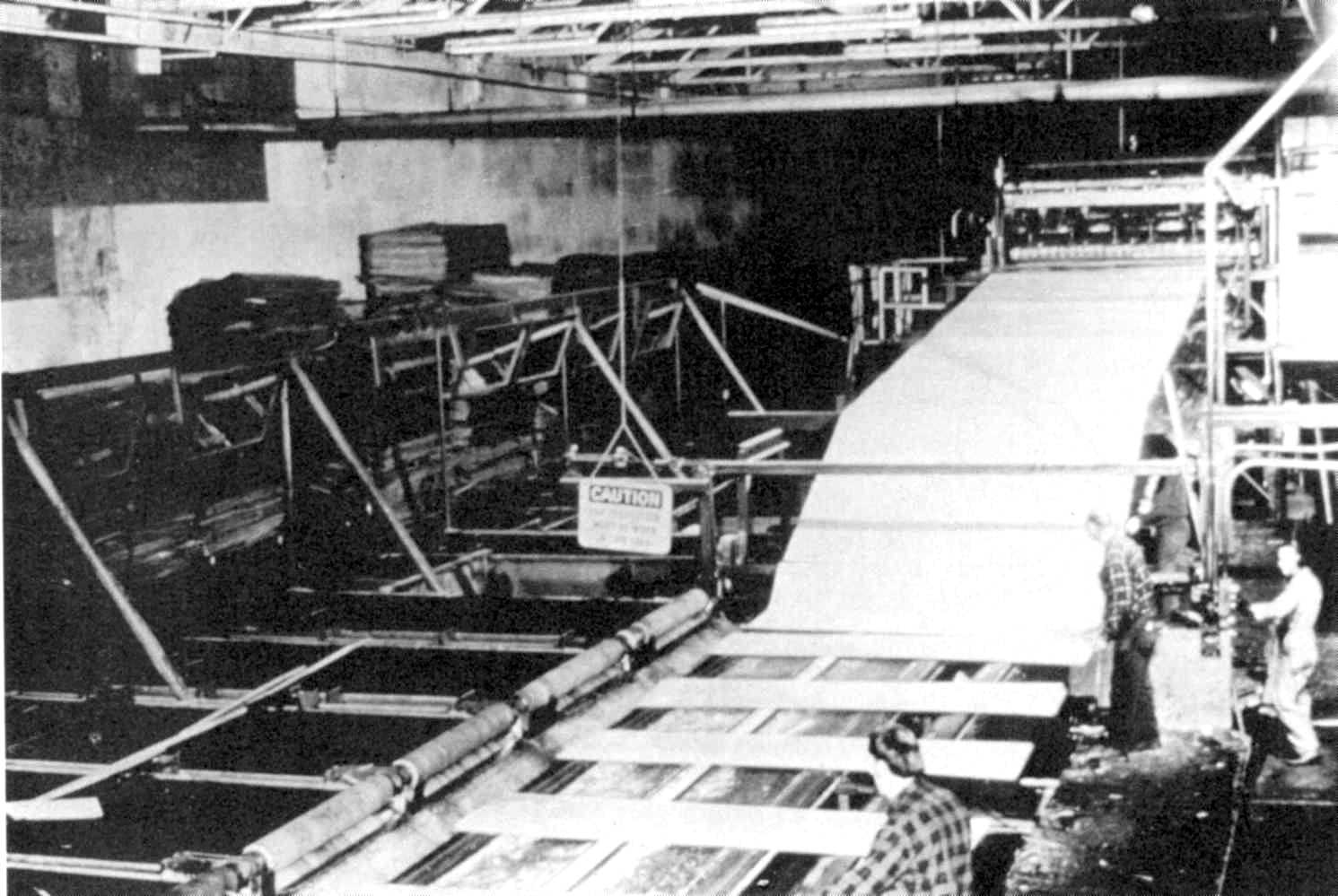

The veneers are then cut in a continuous operation and run through mechanical dryers.

To go back to the plywood main page click here.